Liquid food processing.

Meet high-capacity demands without compromising on quality. Selo’s intelligent solutions ensure your products reach consumers consistently, efficiently, and at the highest standard.

Fast and reliable liquid food production.

Precision engineering and advanced automation for soups, baby food, and vegetable purees, designed for maximum efficiency.

Selo’s liquid food processing solutions deliver efficient, flexible, and consistent production while meeting strict food safety standards. With intelligent equipment and responsive support, you can cut batch times, reduce downtime, and increase throughput, ensuring every product meets the highest quality.

Ready to accelerate your production?

"*" indicates required fields

Liquid food processing lines.

Fully integrated specialized machinery designed to optimize efficiency, maintain quality, and seamlessly fit into your facility.

Made to maximize your performance.

Manufacturing liquid food today demands efficiency without compromise. Every process must maintain complete recipe control to deliver consistent, high-quality products consumers will repeat buy. Selo’s intelligent processing solutions help you optimize production, safeguard quality, and meet demand with confidence.

Maximize precision

Ensure every batch meets your specifications, maintaining perfect taste, texture, and quality every time.

Maximize efficiency

Scale output and optimize throughput for fresh or long shelf-life products without compromising quality.

Maximize safety

From sterile sealing to clean production practices, guarantee food safety and consistent product quality across every batch.

Soup production lines

Selo designs fully automated soup production systems that are flexible, reliable, and precise. From the careful, precise sautéing of onions and garlic for rich, flavorful bases to producing fresh or long shelf-life soups, our solutions maintain perfect taste and texture, at capacities from 250 to 3,000 kg per hour and beyond. They can also be combined with integrated packaging to streamline your operations.

Baby food lines

Producing baby food requires the highest standards of hygiene and safety. Selo designs fully automated baby food production systems that are reliable, precise, and easy to integrate with capacities from 250 to 2,000 kg per hour – and built to keep scaling with you. Our solutions ensure every batch meets stringent quality standards while maintaining efficiency, consistency, and peace of mind throughout your operations.

Streamlined operations

Tailored production lines and expert guidance for smooth, efficient, and future-ready operations.

Production experts

Over 80 years of industry know-how delivering lean, sustainable, and high-quality production.

Sustainable performance

Eco-conscious technologies that reduce costs, increase efficiencies, and elevate product excellence.

The perfect line for your product.

01

Design + develop

At Selo, we create liquid food production lines tailored to your recipes, current capacity, and future growth. From concept to completion, every system is designed to maximize efficiency, ensure consistent quality, and support your operational goals. In our Technology Testing Center, we refine every detail — texture, flavor, consistency, and shelf life — so your production line is optimized for high performance from day one.

02

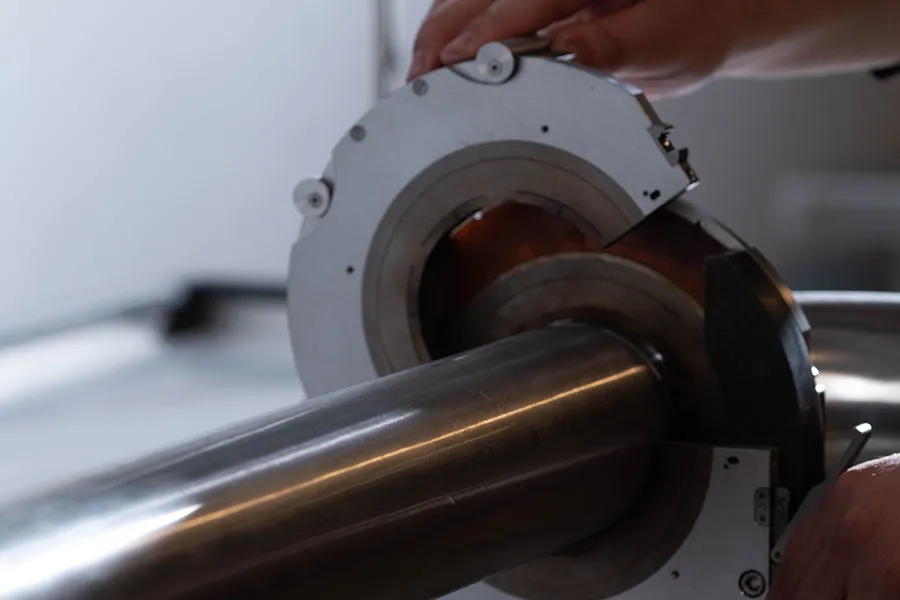

Build + install

Our team assembles and integrates your liquid food line on-site with precision and care, ensuring each component works seamlessly. Rigorous FAT and SAT testing confirms hygienic, high-capacity, and reliable performance, helping you maximize throughput, reduce downtime, and maintain consistent product quality and safety.

03

Support + optimize

Selo’s commitment doesn’t end at installation. We provide ongoing remote and on-site support, preventive maintenance, operator training, and spare parts guidance, ensuring your line continues to operate efficiently, safely, and at optimal performance — today and as your production scales for the future.

Why liquid food manufacturers partner with Selo.

Proven success

With over 2,500 projects across six continents, Selo brings 80 years of expertise to every project. Your production is in safe hands with Selo.

Custom design

Work with industry leading engineers to create a line tailored to your recipes, capacity, and goals, ensuring your production is efficient and reliable.

Integrated support

Design an aftersales package that suits your setup, with remote and on-site support from the engineers who built your line, keeping it running at consistent performance.

What our clients say.

Manufacturers worldwide trust Selo to streamline production, maximize efficiency, and deliver consistent, high-quality products at scale…